ABC OF SUSTAINABILITY IN PACKAGING

Sustainability management nowadays continues to pose many problems for all those who try to operate in “green mode”, and the amount of information we receive on a daily basis does not always clarify our ideas.

We always reiterate, perhaps too often, that sustainability is a question of sense and sensitivity, but we do so because we still think that it is the real key. Designing with precise techniques and necessary aesthetic sensitivity is fundamental to developing truly efficient and ecological, yet impressive, packaging.

Sometimes, gigantic efforts are made to develop a product (in our case we always talk about cardboard and paper packaging), with very specific and ecological characteristics that, later, seen from another point of view, turns out to be not so efficient.

For example, using recycled raw materials and then discovering that the process of recycling these raw materials causes much more GHG emissions to the planet than using virgin fibre paper.

Alternatively, opting for a much more innovative and recyclable material only to discover that there is no advanced technology available on the market to recycle that material.

Don’t be alarmed, this is part of the change process.

In the end, however quickly we want to cook a stew, getting it right is basically a matter of simmering it over a low heat.

All these kinds of initiatives and tests are absolutely necessary, they build the basis of experience and practice on which to model all waste management and environmentally efficient production processes.

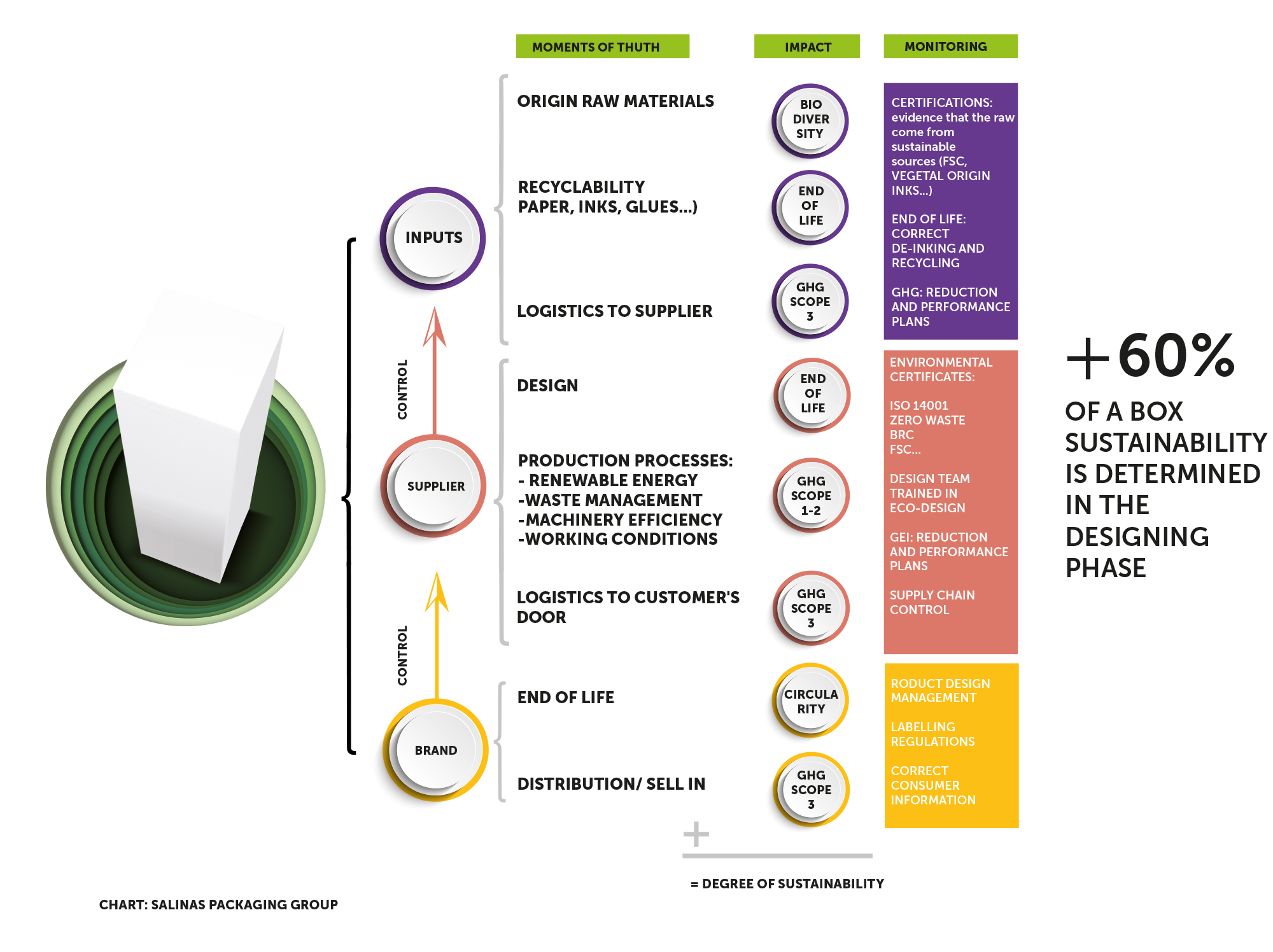

Just like a customer journey, sustainability also has its moments of truth. Knowing them is essential to improve, advance and, above all, to have data collection techniques.

Importantly, they should not only be familiar to development teams, as more than 60% of a pack’s sustainability is decided in the design phase.

We have summarised these moments of truth in the following figure.

A box’s sustainability ranges from the management of natural resources, through the energy used to transform it into a box, the management of industrial waste and, of course, the distribution along the entire chain.

Let’s get rid of the idea that a box is more sustainable just because it is made from recycled paper.

THE PAPER ISSUE.

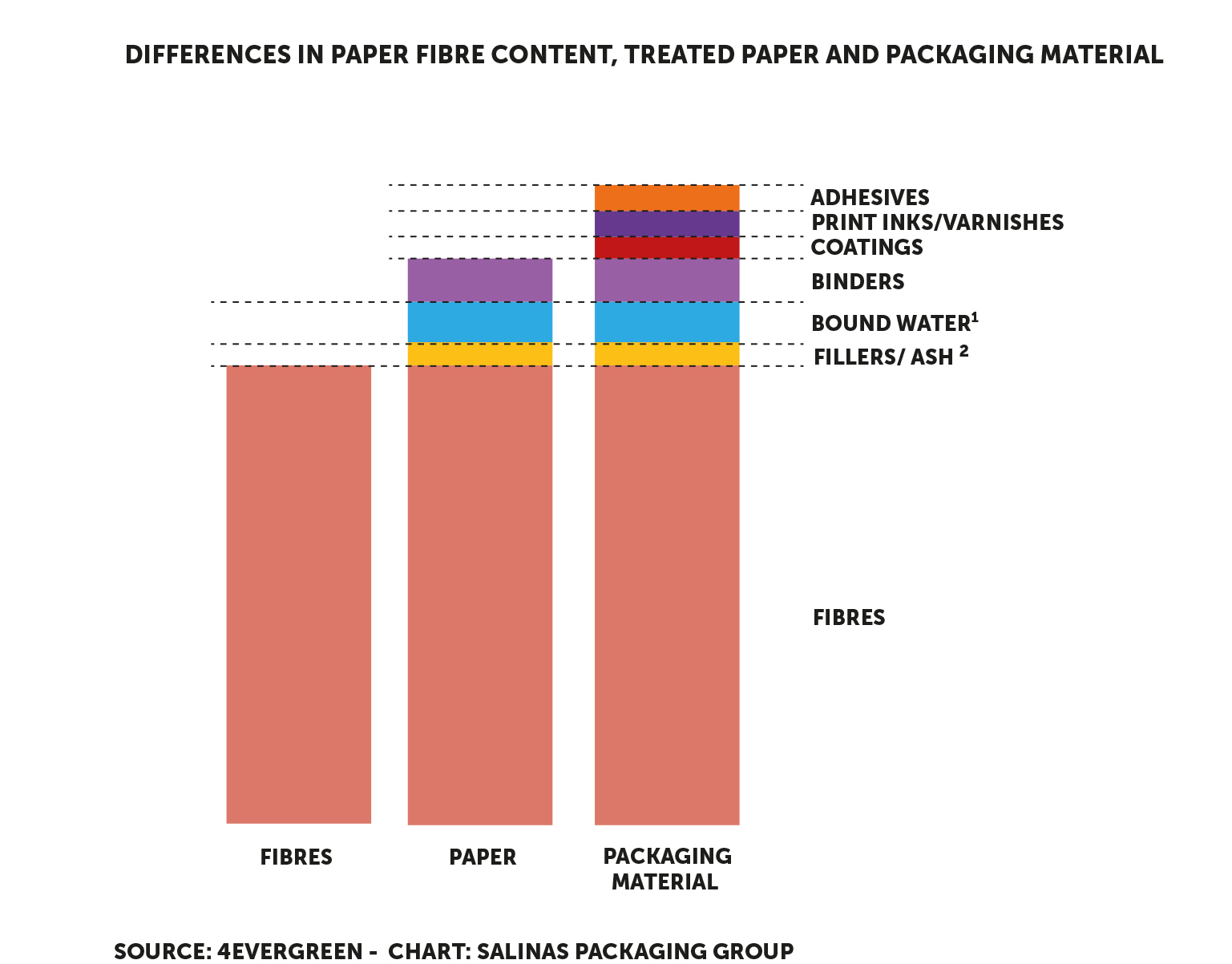

It is important to understand that when we design, develop and produce a case, we are adding processes to the paper that determine upstream what the ecological index is and downstream the correct end of life of the product.

Three basic aspects to consider when evaluating a material:

– VIRGIN OR RECYCLED FIBRE? It depends, but as we are talking about the luxury market, a mix of both is ideal.

Why? Paper is one of the materials that can be recycled the most times into a new raw material (about 25 times), however, the recycling process deteriorates those fibres faster and decreases their life cycles.

Blending the two fibres together helps to maintain the volume, quality and properties of the fibre and lengthen the recycling cycles.

Importantly, both virgin, hybrid and 100% recycled fibre can and must have an FSC or PEFC certified origin.

– Not everything is in the fibre, as paper, in order to be paper, needs a bleaching process. Chlorine, which is the element that determines the sustainability of a paper, comes into play in this process.

To put it in a nutshell, the traditional paper bleaching process consists of mixing the pulp with water and chlorine; this chlorine cannot be completely removed from the paper, which means that the paper itself carries a polluting element (without going into dangerous spills).

Fortunately, today there are several types of elemental chlorine-free processes. Worldwide, the use of chlorine-based bleached chemical pulp has decreased by about 70% since the 1990s.

The accepted elemental chlorine free bleaching system in the European Union is ECF, but there are other systems such as PCF (for recycled fibre) and TCF (for virgin fibre) which are completely chlorine free.

– And finally, we will have to measure how it affects all the processes we subject that paper to in order to establish how environmentally friendly and recyclable our packaging is. Both the Graphic Arts processes and the production processes, i.e. the corporate efficiency and sustainability of each supplier.

BETTER UNDERSTANDING THE CONCEPT OF RECYCLING IN PACKAGING

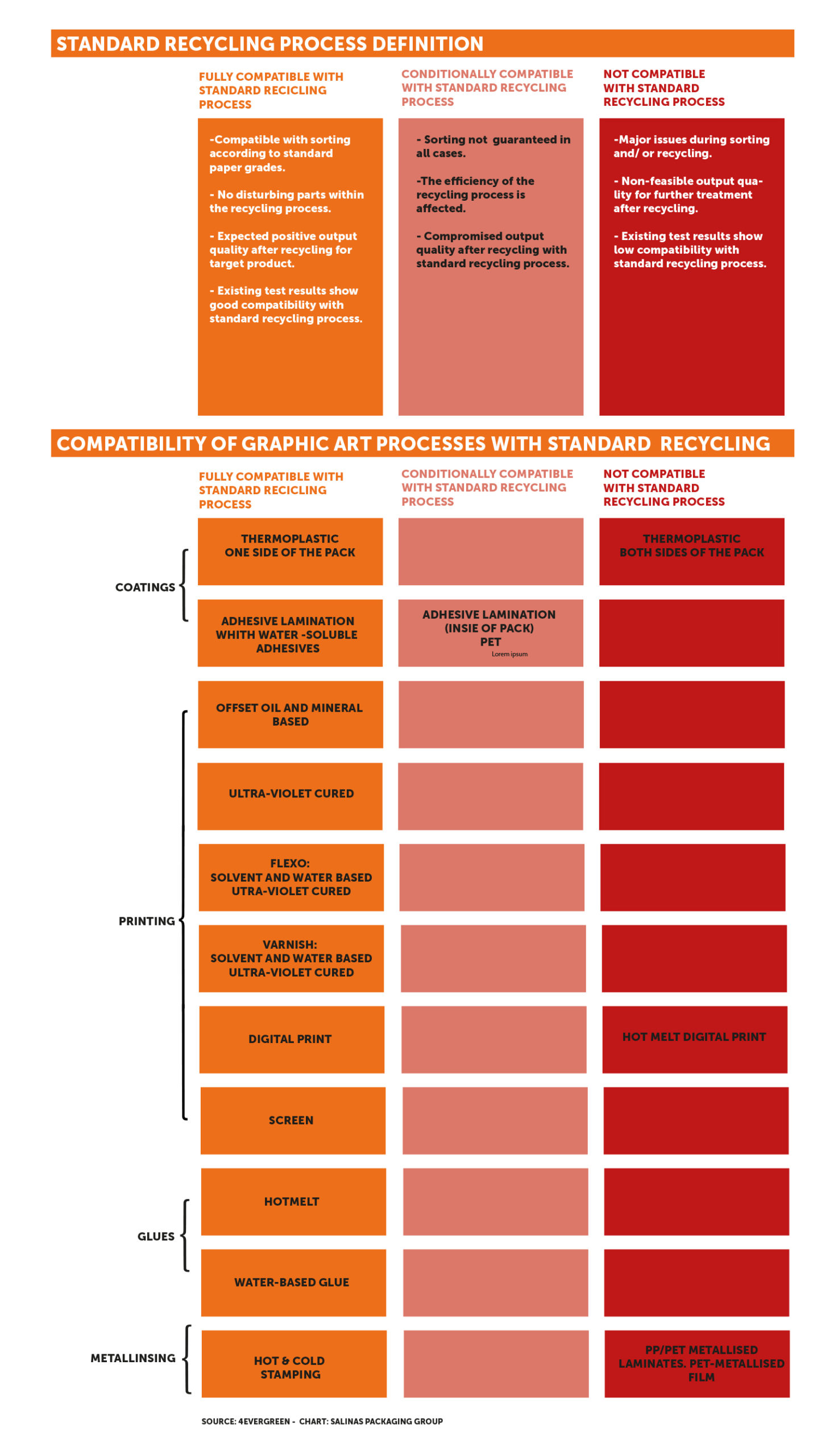

Just like different bleaching processes, there are also different recycling techniques: standard mill, de-inking / flotation mill or specialised mill…

The table below is a summary of the information provided by the DESIGN GUIDELINE FOR FIBRE BASED PACKAGING published in 2022 by @4EVERGREEN and focuses on the standard process.

We find it interesting to focus on this standard system, as we can control how and where we make our product, but we have no control over where the waste from our packaging will be produced.

Lastly, it is worth mentioning that a lined case will always be destined to return to cardboard and not to paper, as the material with the most weight in a case as a whole is always cardboard, which, moreover, has a recycled origin.

This is a basic guide to understand what to measure and why in the exciting process of designing, developing and producing a lined case.

We thought it would be interesting to synthesise the whole process to offer a 360º view of the important moments, in terms of sustainability, during the entire development and production process.

We promise to go deeper into each of these stages in future instalments.

We hope you find it interesting and useful.